Tires are the crucial connection between your car and the road. Their performance directly affects your safety and driving experience. Beyond the wear and tear from everyday use, tires also face the silent threat of aging. The latter is a process accelerated by factors like exposure to heat, ozone, and even water. Rain, for example, can cause tires to age faster due to the absorption of water molecules, which can weaken the rubber's structure.

Understanding the science behind tire durability becomes critical for ensuring a safe and reliable ride. One key factor in this equation is a property called glass transition temperature (Tg). It dictates a tire's ability to withstand the stresses of heat and changing conditions. You might not realize it, but tires have a "sweet spot" when it comes to temperature - a point where they perform best. This "sweet spot" is directly related to Tg.

Tg is the temperature at which a material transitions from a rigid, glassy state to a more flexible, rubbery state [1]. Think about a gummy bear. At room temperature, it's flexible and chewy, but put it in the freezer, and it becomes hard and brittle. That's because the gummy bear's Tg is somewhere above room temperature.

For tires, a crucial factor in determining their durability and performance is their Tg. That's because it impacts their ability to handle heat generated by friction and road conditions. The lower the Tg, the better the tire's ability to withstand heat and remain flexible, preventing premature wear and tear. This is why tire manufacturers invest significant effort in designing tires with optimal Tg values.

How Do Researchers Predict Tg for Different Tire Materials?

A team of researchers [2] recently used molecular dynamics simulations to predict the Tg of various rubber materials commonly used in tires:

- Natural Rubber (NR): Composed mainly of cis-1,4-isoprene, NR's Tg is relatively easy to predict;

- Butadiene Rubber (BR): BR is a complex mix of cis-, trans-, and vinyl-butadiene, making Tg calculation more challenging;

- Styrene Butadiene Rubber (SBR): SBR contains styrene in addition to butadiene, further complicating Tg prediction.

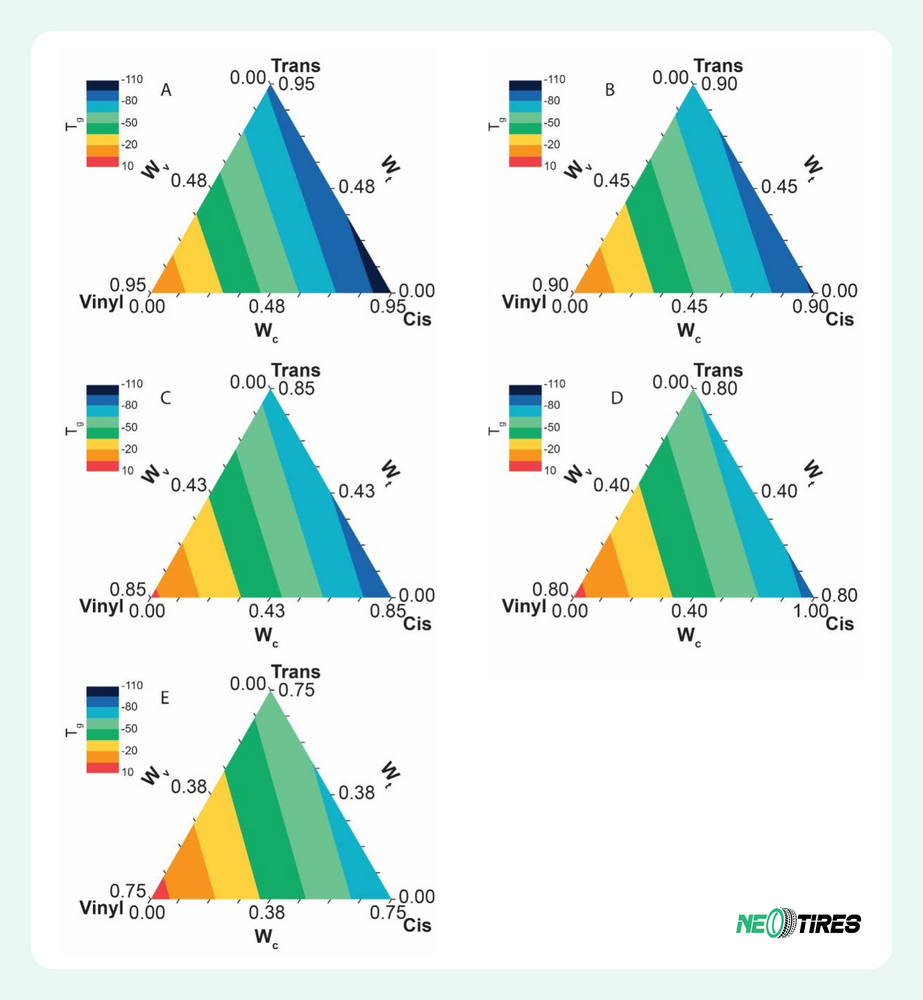

By running simulations on these materials, the researchers modeled the behavior of molecules at different temperatures and observed how the transition from a glassy to rubbery state occurred. The researchers found that the Tg of cis-butadiene was –110°C, trans-butadiene was –98°C, and vinyl-butadiene was –8°C. These findings were further used to develop a new equation to predict Tg for BR, taking into account the different types of butadiene isomers present. They also created a ternary phase diagram for Butadiene Rubber (BR) (Fig. 1), revealing how Tg changes as the composition of cis, trans, and vinyl butadiene varies.

Fig.1. Ternary phase diagram for Butadiene Rubber

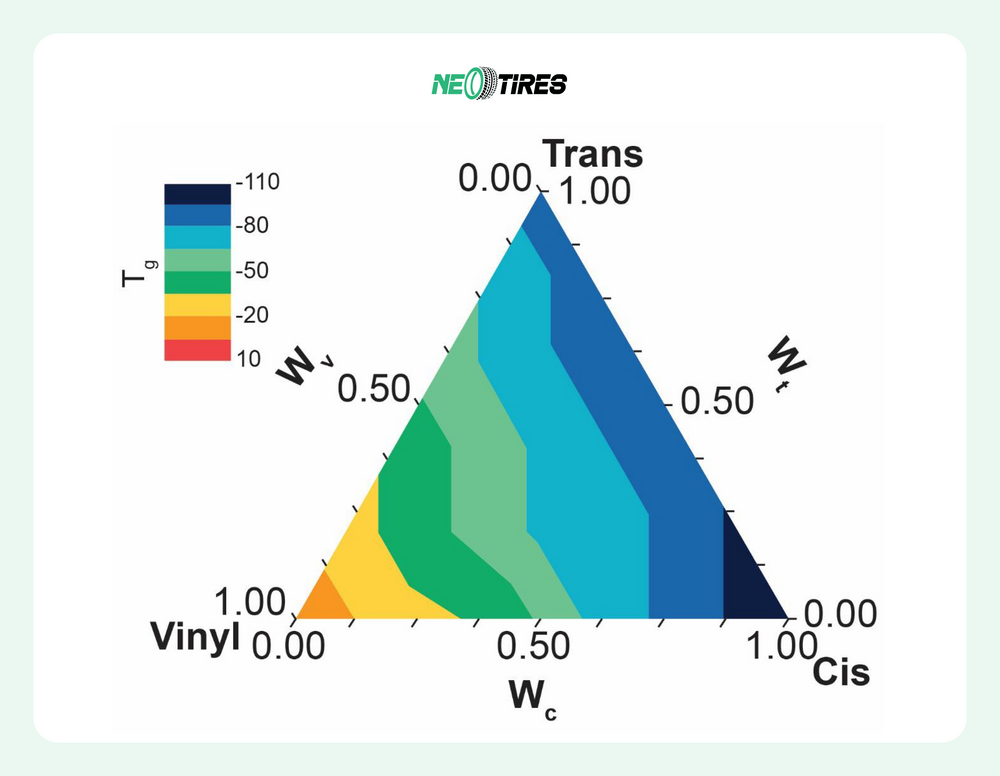

Additionally, a ternary phase diagram was created for Styrene Butadiene Rubber (SBR), demonstrating the relationship between Tg, styrene content, and the different butadiene isomer compositions (Fig. 2).

Fig. 2. The Ternary Phase Diagram for SBR demonstrates the relationship between Tg, styrene content, and the different butadiene isomer compositions

Why Is This Research Significant?

These findings provide a valuable tool for tire manufacturers:

- Rational Tire Design: This research enables them to design tires with optimized Tg for specific performance requirements and conditions. For example, tires designed for high-performance driving often require a higher Tg to handle the increased heat generated, while tires designed for winter conditions might need a lower Tg for optimal flexibility at lower temperatures;

- Enhanced Durability: By carefully controlling the composition and Tg, manufacturers can improve the thermal stability of tires and increase their lifespan. A well-designed tire with the right Tg will be less likely to experience cracking or other forms of degradation caused by exposure to extreme temperatures;

- Improved Safety: Tires with optimal Tg values are less likely to fail at high temperatures, contributing to safer driving experiences. A tire that's too brittle due to a high Tg might lose its grip under pressure, potentially leading to a dangerous situation.

The performed studies [2] demonstrate the power of using molecular simulations to predict material properties and optimize design for a crucial component of our vehicles – the tires. As we continue to push the boundaries of vehicle performance and safety, understanding the science behind Tg and how it affects tire design will become increasingly important.

References:

[1] Sommer, J.G., 2009. Engineered Rubber Products. Hanser Publishers, Munich, 1–181.

[2] Ryu, M.S., Kim, H.G., Kim, H.Y., Min, K.S., Kim, H.J., Lee, H.M., 2017. Prediction of glass transition temperature and design of phase diagrams of butadiene rubber and styrene butadiene rubber via molecular dynamics simulations. Physical Chemistry Chemical Papers 25, 1–12.