Run-flat tires for passenger cars, SUVs, and light trucks are designed to keep your vehicle moving even after a puncture, typically for up to 50 miles at speeds up to 50 mph. Understanding how run-flat tires work begins with their structural design: Instead of going completely flat when air escapes, run-flat tires maintain enough structural integrity to support the vehicle’s weight temporarily. This technology gives drivers time to reach a repair shop safely, without pulling over on the roadside immediately to replace the flat tire.

Run-Flat Tires Meaning

Run-flat tires are engineered to run at zero internal pressure, fully loaded, for a maximum of 50 miles at 50 mph, due to their advanced bead design and reinforced sidewalls or internal support rings that allow limited driving after a loss of air pressure.

A run-flat tire remains functional long enough for controlled driving to safety or to a service station, unlike regular tires, which usually collapse once pressure drops.

How Do Run-Flat Tires Work?

Run-flat technology relies on tire structural reinforcement that prevents complete tire collapse when air pressure is lost, along with an advanced bead system. There are two primary systems used in modern run-flat tires to achieve structural reinforcement: the Self-Supporting Run-Flat System and the Support Ring System. Here is the breakdown:

Advanced Bead Design

A technical aspect of run-flat tires is their bead design, where the tire meets the rim. Run-flats often feature specially engineered beads that grip the wheel more securely, preventing the tire from unseating when deflated- a crucial factor in maintaining control during sudden air loss.

Self-Supporting Run-Flat System (Most Common)

Self-supporting run-flats use reinforced sidewalls made from heat-resistant rubber compounds that are significantly thicker and stiffer than standard tire sidewalls. Here's the engineering behind it:

Material Composition:

Tire manufacturers combine polyimide with glass fiber and use the mixture in the rubber used to create the tire's sidewalls, thereby increasing the sidewalls' load-bearing capacity. Manufacturers often use materials such as aramid fibers, as in Kevlar, or specialized composites to balance durability and weight.

Normal Operation:

When properly inflated, the reinforced sidewalls of run-flats work similarly to regular tires, with air pressure supporting the vehicle's weight. The stiffer construction is generally noticeable during regular driving.

After Air Loss:

When a puncture occurs and air escapes, the reinforced sidewalls become load-bearing structures. Instead of the tire folding under the vehicle's weight (which would cause the rim to contact the road), the heat-resistant sidewall rubber maintains its shape and supports the vehicle.

Why 50 Miles at 50 MPH?

The 50-mile, 50-mph limit for run-flat tires comes from heat, stress, and material endurance factors.

When a run-flat tire loses air pressure, its reinforced sidewalls flex to carry the vehicle’s weight. This flexing generates friction and heat, which can weaken the rubber and internal steel-fabric structure. Driving faster intensifies that heat and speeds up degradation, while driving slower doesn’t extend the safe range - the limit remains about 50 miles at up to 50 mph.

Even advanced designs, such as Bridgestone’s DriveGuard with sidewall cooling fins, can’t entirely prevent internal damage once the tire runs deflated. After about 50 miles, most manufacturers consider the tire unsafe to use.

Common Self-Supporting Models

- Bridgestone DriveGuard

- Michelin ZP (Zero Pressure)

- Continental SSR (Self-Supporting Runflat)

Support Ring System (Less Common)

Support ring run-flats use a hard internal ring, typically made of reinforced rubber or composite materials, mounted to the wheel inside the tire. When air pressure is lost, the tire's weight rests on this support ring rather than the sidewalls.

Advantages:

- Can handle heavier loads than self-supporting designs

- Used in armored or luxury vehicles requiring maximum reliability

Disadvantages:

- More expensive

- Requires specialized wheels

- Heavier overall assembly

Common Support Ring Models

- Pirelli Run Flat (select models)

- Michelin PAX System (discontinued but still in use on some vehicles)

Run-Flat Systems: Comparison Table

The table below illustrates how run-flat tires work using two distinct engineering approaches, each with specific advantages depending on vehicle type and usage requirements.

Feature | Self-Supporting Run-Flat System | Support Ring Run-Flat System |

Primary Concept | Tire has reinforced sidewalls that can bear vehicle weight after air loss | Tire mounts on a wheel with a hard internal support ring (rubber or composite) |

Main Components | Heat-resistant sidewall rubber + stiffer bead area | Standard sidewall + internal ring mounted on rim |

Driving Distance After Puncture | Up to 50 miles at 50 mph (depending on load) | Up to 125 miles at 55 mph (especially for armored or heavy-duty vehicles) |

Ride Comfort | Slightly stiffer due to reinforced structure | Smoother, closer to regular tires |

Heat Resistance | Moderate; relies on high-temp compounds | Very high; the ring absorbs heat and stress |

Repairability | Usually non-repairable after running flat* (*brand dependent) | Also non-repairable, but less prone to sidewall damage |

Weight | Slightly heavier than a standard tire | Significantly heavier due to ring installation |

Common Users/Brands | Passenger vehicles, BMW, Lexus, MINI / Bridgestone DriveGuard, Michelin ZP, Continental SSR | Luxury sedans, armored vehicles / PAX System (Michelin), Pirelli Support Ring |

TPMS Requirement | Yes, mandatory | Yes, mandatory |

Market Availability | Widely available | Rare, limited to OEM or specialized markets |

Note: Some manufacturers, such as Michelin, Bridgestone, and Dunlop, have developed a few proprietary or hybrid systems, but they are variations of these two core concepts.

Regardless of which system is used, understanding how run-flat tires work also requires knowing about the critical safety technology that monitors them: TPMS.

The Role of TPMS (Tire Pressure Monitoring System)

Since run-flat tires continue to perform even when flat, all run-flat tires, regardless of the specific system type, may only be used on a vehicle equipped with a Tire Pressure Monitoring System (TPMS). The TPMS generally alerts drivers as soon as one of the tires loses pressure. A side effect of the stiffer run-flats’ construction is that the sidewalls do not bulge at low air pressure, making it critical to have a working tire pressure monitoring system.

Without TPMS, drivers might:

- Continue driving beyond the 50-mile limit

- Exceed 50 mph on a deflated tire

- Cause irreparable damage to the tire and potentially the wheel

✅ NeoTires Safety Note: TPMS (Tire Pressure Monitoring System) is mandatory for all new passenger cars and light trucks, with or without run-flat systems. Without TPMS, drivers might not notice pressure loss, leading to further damage (NHTSA, 2005).

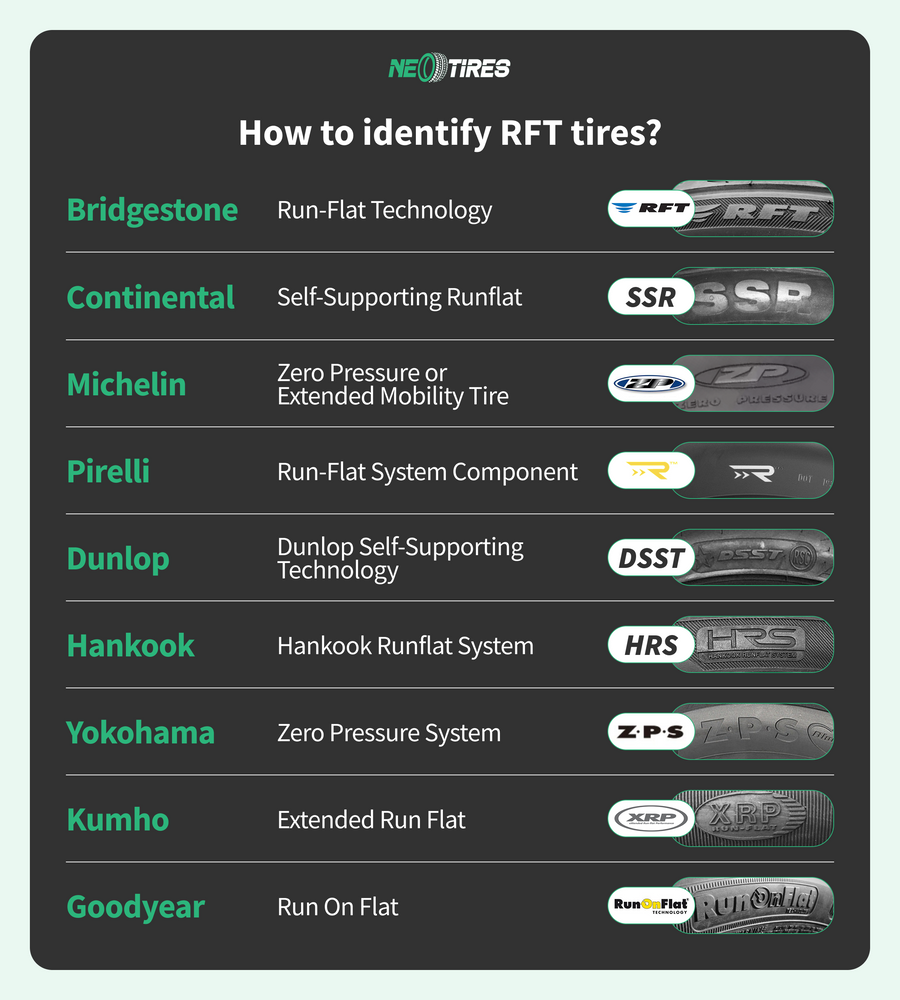

How to Identify Run-Flat Tires

Manufacturers mark run-flat tires with specific labels on the sidewall. Look for one of these designations:

Brand | Label | Meaning |

Bridgestone | RFT or Run Flat | Run-Flat Technology |

Continental | SSR | Self-Supporting Runflat |

Michelin | ZP or EMT | Zero Pressure or Extended Mobility Tire |

Pirelli | RSC; Run Flat; "RunForward" symbol | Run-Flat System Component Run Flat; Symbol as an elongated “R”with small arrows underneath |

Dunlop | DSST | Dunlop Self-Supporting Technology |

Hankook | HRS | Hankook Runflat System |

Yokohama | ZPS | Zero Pressure System |

Kumho | XRP | Extended Run Flat |

Goodyear | ROF or EMT | Run On Flat/ Extended Mobility Tire for older models |

Check the owner’s manual or the tire’s sidewall lettering if you’re unsure whether your vehicle supports a run-flat system. Discover the Best Run Flats To Consider if you decide to make a switch.

Why Were Run-Flat Tires Developed?

Run-flat tires were created to address safety and convenience issues associated with traditional tire punctures.

Safety Motivation: The main goal was to reduce tire-related emergencies while driving and remove the need to change tires on busy roads. The National Transportation Safety Board (NTSB) report indicates about 33,000 tire-related passenger vehicle crashes each year.

Military Origins: Run-flat technology started in the military during the 1930s, where keeping vehicles mobile in hostile situations was essential. Armored vehicles and military transports needed tires that could withstand damage without stopping the vehicle.

Consumer Market Introduction: Bridgestone released the first consumer run-flat tire in 1987 for the Porsche 959. However, it wasn't until the mid-2000s that more people began using them when:

- TPMS became federally required in 2007

- Luxury car makers like BMW started equipping vehicles with run-flats from the factory

- Manufacturing costs dropped enough to make run-flats viable for a larger market

Modern Advantages: Today’s run-flat tires remove the need for spare tires. These tires reduce vehicle weight, increase trunk space, improve fuel efficiency, and align with design goals, making them a favorite option for BMW cars.

Are Run-Flat Tires Worth It?

Yes, run-flat tires are worth it if convenience and safety are a priority to you, even at the expense of a higher price, higher maintenance costs, and a stiffer ride. For a detailed breakdown, see our article on run-flats pros and cons: Run-Flat Tires: Advantages and Disadvantages

Frequently Asked Questions

About Run-Flat Technology

What Does "Run-Flat" Mean On a Tire?

"Run-flat" refers to pneumatic vehicle tires designed to maintain their shape after a puncture, allowing the car to be driven for 50 miles at around 50 mph after complete air pressure loss. This technology eliminates the immediate need to stop and change a tire on the roadside.

How Do Run-Flat Tires Work?

Run-flat tires keep their shape after losing air by using either reinforced sidewalls or internal support rings. Self-supporting run-flat tires have sidewalls about ¾" thick, while standard tires have sidewalls that are only ⅛" thick. This extra thickness lets them support the weight of the vehicle even without air pressure. Support ring systems use a hard internal ring to carry the vehicle's weight when deflated.

What's The Difference Between Self-Supporting and Support Ring Run-Flat Tires?

Self-supporting run-flat tires have reinforced sidewalls that hold the vehicle's weight after losing air. Support ring systems use a hard internal ring placed between the tire and the wheel. Self-supporting tires usually allow for 50 miles of travel at 50 mph after deflation and are often found on passenger vehicles. Support ring systems can manage heavier loads and travel longer distances, but they need special wheels. Run-flat tires weigh 20% to 40% more than standard tires, and support ring systems are much heavier because of the extra ring.

Why Are Run-Flat Tires Limited to 50 miles at 50 mph After Air Loss?

The 50-mile and 50-mph limits address issues related to heat and structural stress. Driving at higher speeds produces more heat and speeds up tire wear. The high internal temperatures can break down the rubber and damage the steel and fabric inside.

Why Do Run-Flat Tires Require TPMS?

Because of the stiffer run-flat tire construction, the sidewalls do not bulge at low air pressure. This makes it essential to have a working tire pressure monitoring system. Drivers could exceed the 50-mile/50-mph safety limits, which can lead to catastrophic tire failure, wheel damage, or loss of vehicle control.

Related Questions About Run-Flat Tires

Are Run-Flat Tires Filled With Air Like Regular Tires?

Yes, run-flat tires need the right air pressure just like regular tires. Run-flat technology depends on air pressure to support the vehicle's weight. The sidewall reinforcement of run-flats allows you to maintain control when you lose all air pressure suddenly; this is where the run-flat feature kicks in. Regular pressure checks remain essential for run-flats to ensure good performance and longer tread life. Run-flat tires cannot deliver their intended performance benefits without the right inflation.

Do Run-Flat Tires Need To Be Replaced After Being Driven Flat?

It depends on the manufacturer. Most major brands, including Continental, Yokohama, and Pirelli, require the replacement of run-flat tires driven while deflated because internal structural damage cannot be confirmed. However, some manufacturers like Michelin, Kumho, and Hankook permit repair under specific conditions if the tire meets their inspection criteria. The safest approach is to consult your tire's specific manufacturer guidelines and have the tire professionally inspected before deciding whether repair is possible.

Can Run-Flat Tires Be Used On Any Car?

No, run-flat tires should only be installed on vehicles equipped with a functioning Tire Pressure Monitoring System (TPMS). You should consult your driver's manual before making the switch to or from run-flat tires, as compatibility depends on the car's specifications and systems.

Key Takeaways

Understanding how run-flat tires work demonstrates smart engineering that helps keep vehicles moving after losing air pressure. Whether they use self-supporting sidewalls or internal support rings, run-flat systems bring valuable safety benefits when paired with a working TPMS and used according to the manufacturer’s guidelines.

RFT technology removes the need for immediate roadside tire changes by allowing up to 50 miles of driving after total air loss. However, this technology comes with some downsides, such as higher upfront costs, the need for replacement after deflation, and a potentially stiffer ride.

For drivers considering whether run-flat tires are right for their vehicle, it is important to understand both the engineering principles and practical limits. You can learn more about Run-Flat Tires: Advantages and Disadvantages.

Need help choosing tires for your specific vehicle? Contact NeoTires' specialists for expert advice.

References:

- Bridgestone. (n.d.). Run-flat tire technology explained. Retrieved October 28, 2025, from https://www.bridgestonetire.com

- Continental Tires. (n.d.). SSR self-supporting runflat technology. Retrieved October 28, 2025, from https://www.continental-tires.com

- National Highway Traffic Safety Administration (NHTSA). (2005). Federal motor vehicle safety standards; Tire pressure monitoring systems. Federal Register. Retrieved October 28, 2025, from https://www.federalregister.gov

- National Transportation Safety Board (NTSB). (n.d.). Tire-related crash statistics. Retrieved October 28, 2025, from https://www.ntsb.gov

- Qingdao University of Science and Technology. (2021). Optimize design of run-flat tires by simulation and experimental research. PMC. Retrieved October 28, 2025, from https://pmc.ncbi.nlm.nih.gov/articles/PMC7863950/